American manufacturing is the best in the world, backed by cutting-edge technologies, skilled workers, and strong environmental standards.

Investing in innovation will bolster American leadership in advanced manufacturing of steel, concrete and chemicals. Bringing these industries home to produce innovative products will also strengthen the defense industrial base, bolster national security, create thousands of well-paying jobs, and limit our supply chain reliance on adversaries or countries with low environmental standards.

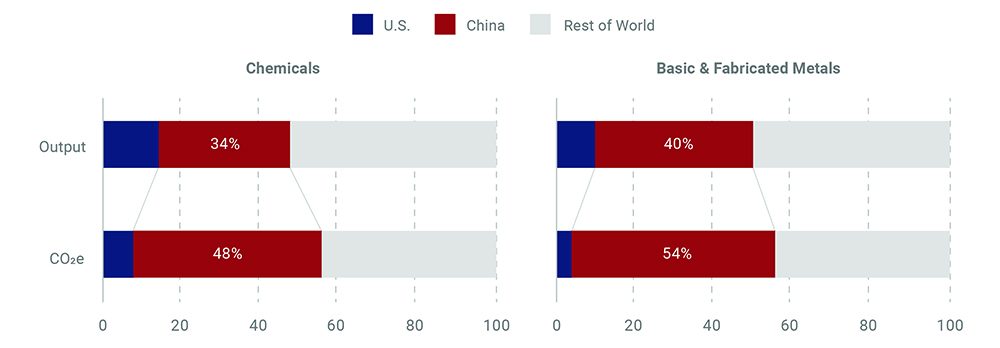

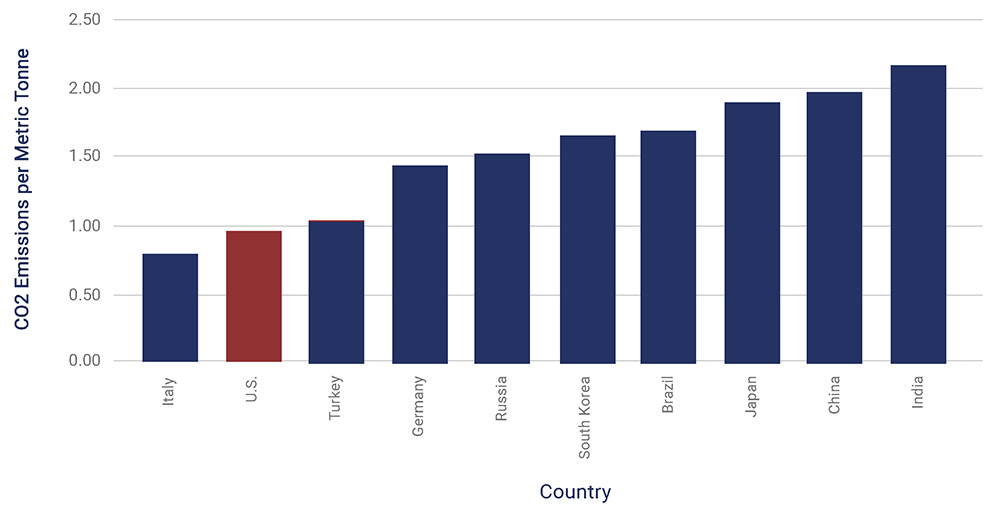

Capitalize on demand growth for clean chemicals. A 35% increase in global demand for chemicals is expected by 2050, providing opportunities for the American industrial base to drive down the cost of innovative technologies, scale energy innovation and create jobs. The U.S. is already the second-largest exporter of chemicals globally, and many importing countries are key U.S. allies. Additionally, many of these trading partners implement demand signals for lower-emission products. This presents a business case for the U.S. to continue exporting clean chemical products while investing in domestic capacity to ensure that these products will be manufactured in the U.S. instead of China.

U.S. cement imports are growing while the developing world builds rapidly. According to the United States Geological Survey (USGS), U.S. cement imports have grown from 15% of domestic consumption in 2020 to 22% in 2024. At the same time, domestic production has been declining. A key reason is the reduction of coal fly ash as a substitute for cement in concrete mixes due to coal plant closures. The U.S. cannot afford to increase its dependence on foreign imports for critical infrastructure material. Instead, we can strengthen domestic supply chains by supporting innovative materials manufactured from domestic sources. This also enables American manufacturers to capitalize on the developing world’s commodity boom, which will lead to using a New York City’s worth of concrete every month, for the next 40 years.

Reauthorize programs enacted in the Energy Act of 2020 that supported a robust, crosscutting clean industrial technologies R&D program to lower the cost of cleaner chemicals, materials, and manufacturing.

These programs can de-risk first-of-a-kind demonstration projects of clean industrial technologies. Initial government support for demonstrations is crucial to help first movers in the industrial sector overcome the ‘valley of death’ and reach commercial scale.

Support sector-specific legislation that advances clean manufacturing competitiveness, such as the Concrete and Asphalt Innovation Act, and companion legislation IMPACT and IMPACT 2.0, to advance innovative cement, concrete, and asphalt production. Continue support for appropriations for the SUPER program, which the CHIPS and Science Act authorized to bolster low-carbon iron and steel innovation.